Grind gauge

The grind gauge is used to determine the fineness of grind

The grind gauge is used to determine the fineness of grind

During the dispersion process solids of a coating material are pulverized into smaller particles. The dispersion grade has an effect on the physical and optical characteristics of the coating. The grind gage is used for the determination of the fineness of grain and large particles or agglomerates in a dispersion. It does not define the real grain size or grain distribution. Grind gages are used for quality inspection in a production, storage and application of dispersions in the varnish, pigment, printing ink, paper, ceramic, pharma, food and many other industries.

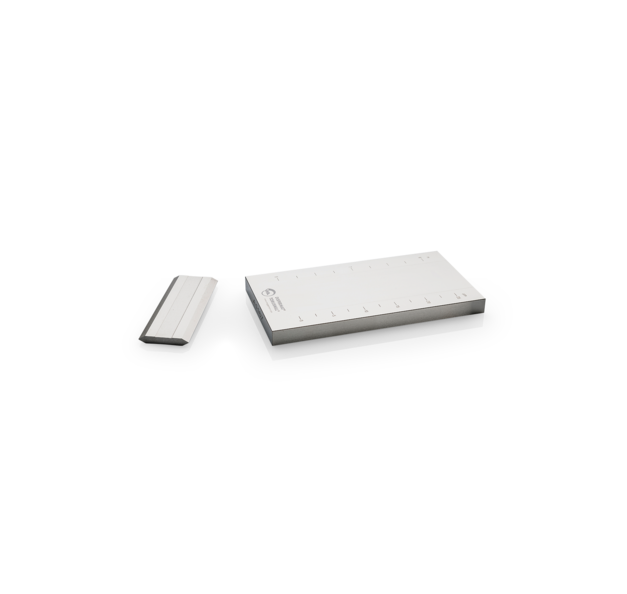

A grind gauge, Hegman gauge or grindometer is a simple tool used to determine the fineness of grind during the dispersion process. It is not used to determine the absolute particle size but is a useful way to follow the fineness of grind. They are commonly used for inspection in production, storage and application of dispersions in varnish, paint, printing ink, paper, ceramic, pharma, food and many other industries. A typical grind gauge consists of a steel block with a single or double groove machined into the surface and a steel scraper.

The grooves decrease in depth from one end of the gauge to the other according to the range of the gauge. To use the gauge, a paint sample is placed at the end of the gauge and the scraper is used to pull the sample down the graduated channel. The fineness of grind is determined by the paint on the scale where the particles become visible.

0 Hegman = 100 micrometer

4 Hegman = 50 micrometer

6 Hegman = 25 micrometer

8 Hegman = 0 micrometer