The Dispersion Process

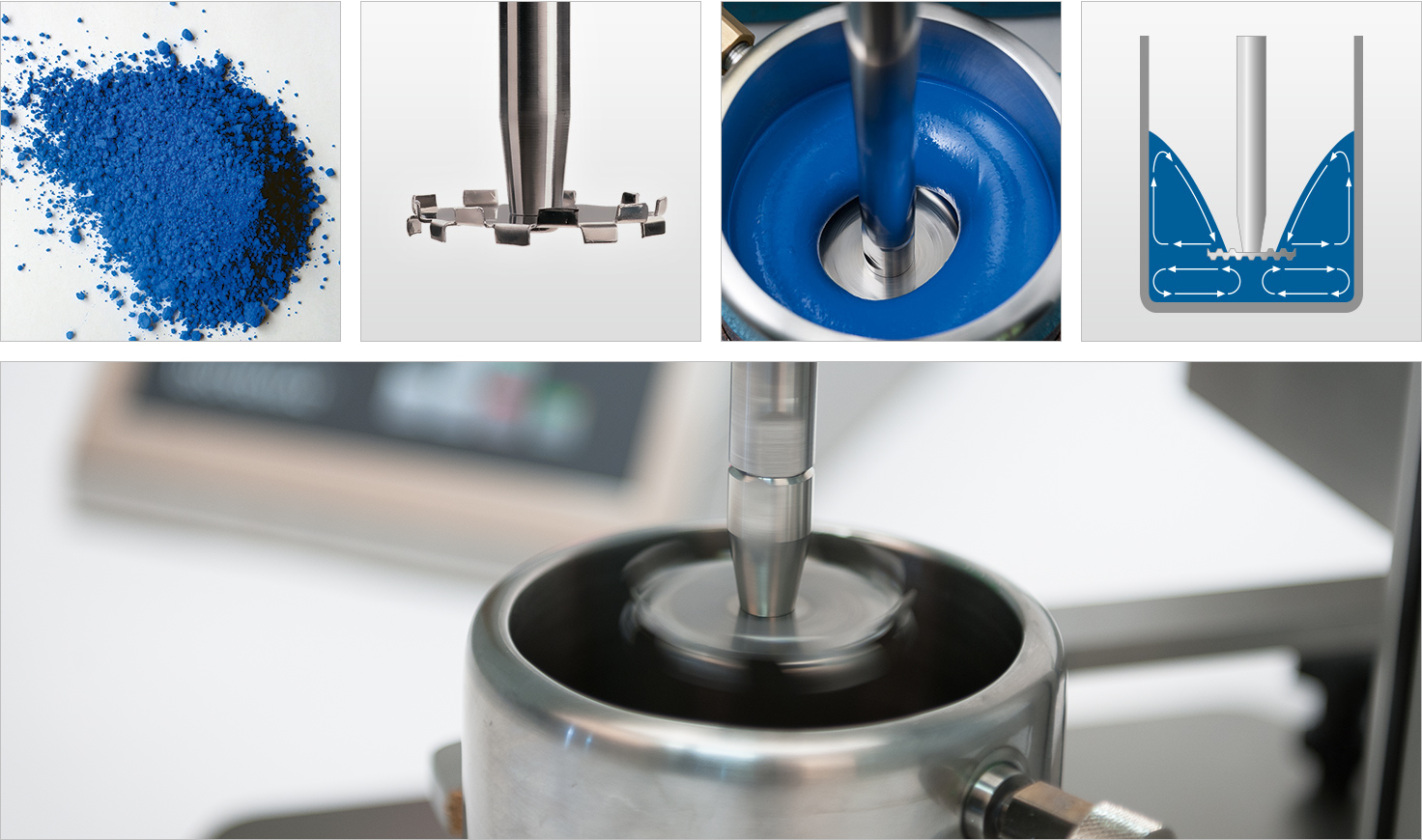

The most important function of the dissolver is the incorporation of solids into liquids. During this dispersion process, three individual steps are performed at the same time:

- Wetting of the surface of the solid particles by the fluid components of the millbase

- Mechanical break down of solid particles associated with each other (agglomerates and aggregates) to form smaller particles

- Stabilization of smaller particles generated during the dispersion process against reagglomeration

The application of a dissolver for high‒speed dispersion differs considerably to stirring and mixing where low speeds and special tools are generally used. A high‒speed dissolver is highly efficient and in many cases all that is needed to achieve the required dispersion result. If however, a finer dispersion result is desired, dispersion becomes a two step process, with the dissolver used for pre‒dispersion, followed by further milling in a bead or basket mill.

Applications for dissolvers include:

- Dyestuffs and varnishes

- Pigments and additives

- Printing inks

- Chemistry

- Plastics

- Construction chemistry

- Electronics

- Adhesives

- Coatings

- Pharmacy and cosmetics

- Microbiology

- Agrochemicals

DISPERMAT® and TORUSMILL®

Durable and highly efficient dispersers, mixers, stirrers, basket mills and bead mills in operation worldwide

VMA‒GETZMANN develops, produces and markets high quality dispersers, mixers, stirrers, bead mills and basket mills. The innovative combination of technology and design as well as high quality are characteristic of our products. Of course, our mixing, dispersing and grinding equipment have integrated safety devices according to the EC Machinery Directive 2006/42 / EC.

Working together with the client our specialists optimize the essential process engineering and the most suitable system solution. Our involved development and design team comes with innovative ideas and long time experience in the mixing, dispersing and grinding technology. We produce with the most modern machine tools and therefore we guarantee a high standard of quality. We prove our expertise and reliability by also having an excellent after sales service.

Our experience ‒ Your advantage

We would be pleased to show you the impressive work section of our dispersing, mixing, stirring, homogenizing and fine grinding systems DISPERMAT® and TORUSMILL®. Our skilled engineers are available at any time for personal advice.