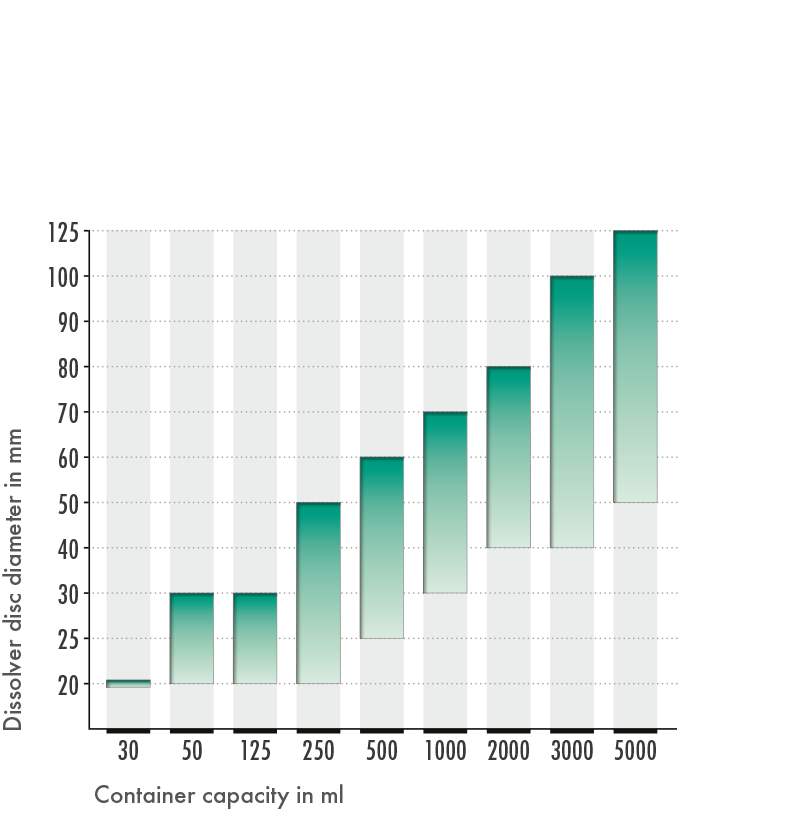

Container sizes and dissolver disc diameters

Recommendation of the container size and dissolver disc diameter as a function of the product quantity and product viscosity

Although the viscosity of the millbase cannot be described by a simple characteristic number, the viscosity must be estimated for tests. In general, the following magnitudes apply:

- low‒viscosity: up to 500 mPs

- medium‒viscosity: 500 ‒ 5000 mPs

- high‒viscosity: over 5000 mPs

The opposite table shows all DISPERMAT® dissolvers, specifying the usable dissolver discs, container sizes and product quantities. The product quantities specified there refer to high‒viscosity products normally used for a dispersion of millbase pastes. Approximately, two times the volume and three times the volume are applicable to medium‒viscosity products or low‒viscosity products, respectively. Once the product volume has been defined and the viscosity has been assessed, the figure (see below) can be used to select the appropriate container size and the matching dissolver disc. When selecting the suitable dispersion container, make sure that the product volume is not above or below approx. 40 to 70 percent of the container volume.

Also, the circumferential velocity (18 to 25 m/s) of the dissolver disc must be kept during the dispersion process. The dissolver is both a pre‒dissolver and an end dissolver.

If the dissolver cannot provide the desired fineness, the product is further processed by a stirrer ball mill after the desired final fineness has been achieved.

25. - 27.03.2025

ECS 2025

Hall 4 / Booth 4-114

Nuremberg, Germany

Experience our dispersion technology! Know-how and top quality since 1972.

At our trade fairs, we present our latest innovations as well as a representative exhibition of patented dispersing and fine grinding systems DISPERMAT® and TORUSMILL®.