Scale-up

Scaling up laboratory results to production

An important fact is that the dispersion results obtained with a DISPERMAT® can be scaled up to a production size dissolver. It was mentioned earlier that the dispersion depends upon the rate with which the agglomerates are transported into the zones of shear and on the mechanical power which is transferred into the millbase.

The mechanical power is the parameter that limits the maximum degree of dispersion which can be achieved. The rate at which the transportation of the agglomerates into the vicinity of the dissolver disc takes place, determines the time necessary to reach the optimum dispersion result.

The deagglomeration process mainly takes place within the area of shear which surrounds the dissolver disc. The most effective shearing conditions are found at the tip of the dissolver disc, as this part is moved through the millbase at the highest speed. It is for this reason, that the tip speed (peripheral velocity) is to be considered as the key parameter for scaling up laboratory results to production. This statement refers to the maximum achievable degree of dispersion and not to the time necessary to obtain it.

The DISPERMAT® will normally be faster in dispersing than a production scale machine, as the distance of the agglomerates must cover to reach the disc are shorter than in larger equipment. Exact correlation between the dispersion result with a DISPERMAT® and a larger dissolver will naturally also depend upon comparable temperature conditions. For temperature control, the use of a double wall temperature control container is recommended.

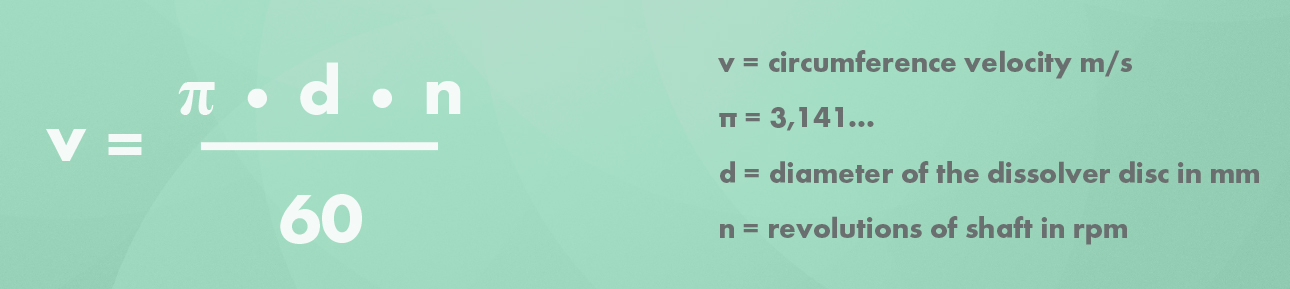

For a laboratory dissolver to reach the peripheral velocities necessary for dispersion, it must be able to run at high‒speeds with utmost accuracy and reproducibility. When using the dissolver discs of different diameters, the circumference velocities may easily be calculated by the mentioned formula.

25. - 27.03.2025

ECS 2025

Hall 4 / Booth 4-114

Nuremberg, Germany

Experience our dispersion technology! Know-how and top quality since 1972.

At our trade fairs, we present our latest innovations as well as a representative exhibition of patented dispersing and fine grinding systems DISPERMAT® and TORUSMILL®.